|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bike Gallery

|

|

|

|

|

|

|

A true tuned exhaust system is

created by harnessing the power of the exhaust pressure wave... When an

engine's exhaust valve opens, the escaping gases create a pressure wave which

travels at the speed of sound down the exhaust system. When this wave reaches

the end of the exhaust system, it  expands, causing a

negative"suction" wave to travel back up thesystem. When this

suction" wave reaches the cylinder, it reverses its direction, going back

in the direction of the original wave. A tuned exhaust system is engineered to

take advantage of this wave action. If the system is designed so that the

negative wave reaches the cylinder as the exhaust and intake valves are open

(the valve overlap period), the suction of the wave will assist in removing

exhaust gases from the cylinder. As the exhaust gases are pulled out faster,

the inlet charge is drawn in faster, increasing volumetric efficiency and

engine power. This effect can be harnessed in a multi-cylinder engine so that

the exhaust pulse of one cylinder enhances the intake of another.

expands, causing a

negative"suction" wave to travel back up thesystem. When this

suction" wave reaches the cylinder, it reverses its direction, going back

in the direction of the original wave. A tuned exhaust system is engineered to

take advantage of this wave action. If the system is designed so that the

negative wave reaches the cylinder as the exhaust and intake valves are open

(the valve overlap period), the suction of the wave will assist in removing

exhaust gases from the cylinder. As the exhaust gases are pulled out faster,

the inlet charge is drawn in faster, increasing volumetric efficiency and

engine power. This effect can be harnessed in a multi-cylinder engine so that

the exhaust pulse of one cylinder enhances the intake of another.

Nitrous , creates power by the addition of more

oxygen and fuel being introduced into the system; however, there are a couple

more benefits of it as well. First, the reduced temperature of nitrous cools

the intake thus helping to provide a denser air charge. Secondly, the nitrogen

atom acts as a buffer and aids in the combustion cycle. The bottle is not just

a container for the nitrous. The pressure at which you run it, will be a

determining factor of your mixture (rich or lean) and the difference in how the

bike reacts in the first 60 feet versus on the big end of the track. When

talking about bottle pressure, the goal is to try and finish the run above

750psi. Why? From zero to 760psi, mass flow of nitrous increases as pressure

goes up numerically. From 760 to 865 there is a very small change, and above

925 there is an enormous decrease in mass flow. How does this translate to the

track? Well, if you started your run at 925psi, as the pressure drops, the mass

flow will increase until getting below the 760 point, at which time mass flow

would begin decreasing. With excessively high or low pressures, you will run

rich in your nitrous/fuel mixture. For a 1/4 mile run, start around 950 psi and

purge the kit two or three times. For 1/8 mile, start at 900 and give it one

good purge.

, creates power by the addition of more

oxygen and fuel being introduced into the system; however, there are a couple

more benefits of it as well. First, the reduced temperature of nitrous cools

the intake thus helping to provide a denser air charge. Secondly, the nitrogen

atom acts as a buffer and aids in the combustion cycle. The bottle is not just

a container for the nitrous. The pressure at which you run it, will be a

determining factor of your mixture (rich or lean) and the difference in how the

bike reacts in the first 60 feet versus on the big end of the track. When

talking about bottle pressure, the goal is to try and finish the run above

750psi. Why? From zero to 760psi, mass flow of nitrous increases as pressure

goes up numerically. From 760 to 865 there is a very small change, and above

925 there is an enormous decrease in mass flow. How does this translate to the

track? Well, if you started your run at 925psi, as the pressure drops, the mass

flow will increase until getting below the 760 point, at which time mass flow

would begin decreasing. With excessively high or low pressures, you will run

rich in your nitrous/fuel mixture. For a 1/4 mile run, start around 950 psi and

purge the kit two or three times. For 1/8 mile, start at 900 and give it one

good purge.

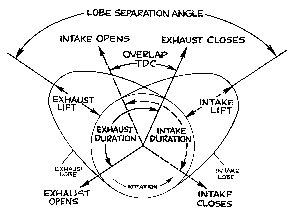

The reason " valve overlap" produces horsepower is because at high R.P.M. when exhaust gases are escaping they draw or pull the intake charge into the combustion chamber for a larger volume of fuel and air.

Lift is the

single biggest profile of a cam that most people look for in their selection.

This simply refers to how far the valve opens (comes off the seat) at its

highest point. If you don't open the valves wide enough, they cause a

restriction. However, based on head flow, intake flow etc., opening too much

will not help at all and in a lot of cases actually hurts. Go turn the water on

in your kitchen sink. The first turn or so, the water comes out quickly and

increases; however, the last bit of turning to full open doesn't change

anything. Get the point? You can only flow as much as the smallest restriction.

Another dynamic that can happen, is the head reaches a stall in flow at a

particular lift. This is exactly the way it sounds, it decreases velocity and can

even result in reversion.

Lift is the

single biggest profile of a cam that most people look for in their selection.

This simply refers to how far the valve opens (comes off the seat) at its

highest point. If you don't open the valves wide enough, they cause a

restriction. However, based on head flow, intake flow etc., opening too much

will not help at all and in a lot of cases actually hurts. Go turn the water on

in your kitchen sink. The first turn or so, the water comes out quickly and

increases; however, the last bit of turning to full open doesn't change

anything. Get the point? You can only flow as much as the smallest restriction.

Another dynamic that can happen, is the head reaches a stall in flow at a

particular lift. This is exactly the way it sounds, it decreases velocity and can

even result in reversion.

Duration simply refers to the amount of time the valve is open. The degrees are a reference to crankshaft degree so a 242º duration means that the valve will be open for 242º of the crank's 360º rotation. More here can be beneficial, but it can also kill a motor too. In a high rpm motor, more duration gives extra time to flow the mixture in or push waste out. This boils down to timing events , but due to the incoming or exiting velocity of the mixture/waste, you can actually continue the sequence without regards to the piston's stroke. The problem with a low rpm motor, is that the valves are open at the wrong time to take advantage of the same things mainly due to the incoming air speed.

The centerline is measurement is the amount of degrees that the crankshaft would have to turn from top-dead-center (TDC) before the lobe is at peak lift. This in conjunction with duration can be used to determine the opening and closing events of the cam. When degreeing in a cam, this is what you are looking for. You want to make sure that the cam is actually ground this way and install it so that it meets your needs.

Lobe separation angle is sometimes confused with centerline, but they are two totally different animals. If you drew a straight line through the center of both the exhaust and intake valves, this number would represent the number of camshaft degrees which separate them. It can never be changed on a single cam engine however most sports and race bikes have two separate cams which allows for even more flexibility. Defining what this number needs to be is done by the lobe profiles chosen, and when you change this angle, you bring a whole new set of variables in as far as the opening and closing events are concerned. This can change the way the motor "sees" the ramps.

Camshaft are Us

Let's talk about those opening and closing

events. Most people think that you open the intake when the piston is going

down the bore, close it at the bottom, have a compression stroke, power stroke,

and then open the exhaust when the piston is coming back up. Well, sort of, and

a lot depends on application, but we are talking performance here; so in that

case it is dead wrong. Cam events will make or break a motor, as you have

heard, the cam is the heart of the engine. The first event we will talk about

is the overlap phase which is where the intake valve opens and the exhaust

closes. The word "overlap" means just that, where the opening/closing

events cross each other. Why would you do that? Well, the spent charge is

moving at a very accelerated rate on the exhaust stroke and just as it is about

to close, the intake valve cracks open and takes advantage of this. The rush of

exhaust acts as a siphon, and although some of the intake charge is lost out

the exhaust, it aids in giving direction of the mixture from the intake into

the cylinder. By moving the mixture in this way, it is not dependant solely on

the suction/vacuum of the piston travelling down the bore. Although some of the

charge is lost, this can actually aid in increasing the velocity of the charge

and promote better cylinder filling. Still don't understand? Get a glass and

two straws and fill the glass about 3/4 full. Place one straw in the glass and

hold it just above the bottom. Take the second straw and put one end in your

mouth and butt the other end against the top opening of the first straw so that

part of the opening protrudes higher than the opening of the straw in the

glass. Now, blow a hard steady stream of air through (air going over the top of

the straw in the glass) and watch the water rise in the straw. If you can blow

long enough it will come out of the top. Now do you understand? There are

caveats to everything, I suppose, and this phenomenon is no different. You can close the exhaust too

early and not take full advantage of it, close the exhaust too late and reduce

volumetric efficiency, and/or open the intake too late and waste your time or

even cause some turbulence. Ever hear someone say, " Turbo

bikes like a wide lobe angle separation like 112º - 114º", but not know

why? A wider lobe

separation angle will yield less overlap . Turbo bikes need a lot less

overlap because they are forced induction and the system is already in a

pressurized state. This does ten-fold what overlap can do as far as cylinder

filling, intake charge, and volumetric efficiency; however, they do need a

little help thus the wider LSA. Too much overlap, and in a pressurized state

like this, the amount of mixture lost is much greater than a naturally

aspirated engine would see, thus working against what the Turbo is

accomplishing. A nitrous bike is much the same in that it is artificially doing

what the turbo do and too much defeats its intended use. A bigger issue is that

if the mixture sees too much of the hot exhaust gasses, it can ignite

prematurely. Too late of

an exhaust closing will cause reversion and bring the hot exhaust back into the

cylinder and besides the pre-ignition chances, the turbulence can disturb the

atomized mixture and create MAJOR problems. Too late on the intake can create a

lean condition, and we know what happens then! As I said, there are

caveats to everything, and though this is the norm for Turbo bikes, there are

tons of those using tight LSA's and making big power, BUT, they are application

specific, and a lot has gone into making the design work. Next we talk about

when the intake valve closes. No, not at the bottom of the intake stroke,

actually, as the piston starts up on the compression stroke! Why? This centers

around the fact that the intake charge cannot come to an abrupt halt just

because the piston stopped moving down. In this way, we take advantage of the

intake charge's inertia to continue filling the cylinder even though the piston

has started up on the compression stroke. The trick is not to close it too

early and lose out on this effect, but also not to close it too late and begin

pushing the mixture back out of the cylinder. This again aids in volumetric

efficiency and increases cylinder pressure in doing so. An improperly phased

cam will do the exact opposite. Okay, now the easy one... the exhaust opening.

Simple! Open it after the power stroke as the piston is moving up on the

exhaust stroke, right? Wrong. The exhaust needs to begin opening shortly before

BDC on the power stroke. Why? Well, first off, the combustion process has

actually spent its energy about 2/3 of the way down and is moving based on the

power stroke of other cylinders at this point. If you wait and open the exhaust

as the piston starts up on the exhaust stroke, it will be pushing against the

spent gases much the

same as it does during the compression stroke. This will rob power from the

power stroke of another cylinder to work

against this force also. Opening the valve before BDC acts as a "pressure-relief"

and then all the piston has to do now is sweep the cylinder clean with its only

obstacle being the back-pressure of the exhaust system. One must be careful not

to try and take advantage of this too quickly though as it would be possible to lose the effect of

the power stroke.

Turbo

bikes like a wide lobe angle separation like 112º - 114º", but not know

why? A wider lobe

separation angle will yield less overlap . Turbo bikes need a lot less

overlap because they are forced induction and the system is already in a

pressurized state. This does ten-fold what overlap can do as far as cylinder

filling, intake charge, and volumetric efficiency; however, they do need a

little help thus the wider LSA. Too much overlap, and in a pressurized state

like this, the amount of mixture lost is much greater than a naturally

aspirated engine would see, thus working against what the Turbo is

accomplishing. A nitrous bike is much the same in that it is artificially doing

what the turbo do and too much defeats its intended use. A bigger issue is that

if the mixture sees too much of the hot exhaust gasses, it can ignite

prematurely. Too late of

an exhaust closing will cause reversion and bring the hot exhaust back into the

cylinder and besides the pre-ignition chances, the turbulence can disturb the

atomized mixture and create MAJOR problems. Too late on the intake can create a

lean condition, and we know what happens then! As I said, there are

caveats to everything, and though this is the norm for Turbo bikes, there are

tons of those using tight LSA's and making big power, BUT, they are application

specific, and a lot has gone into making the design work. Next we talk about

when the intake valve closes. No, not at the bottom of the intake stroke,

actually, as the piston starts up on the compression stroke! Why? This centers

around the fact that the intake charge cannot come to an abrupt halt just

because the piston stopped moving down. In this way, we take advantage of the

intake charge's inertia to continue filling the cylinder even though the piston

has started up on the compression stroke. The trick is not to close it too

early and lose out on this effect, but also not to close it too late and begin

pushing the mixture back out of the cylinder. This again aids in volumetric

efficiency and increases cylinder pressure in doing so. An improperly phased

cam will do the exact opposite. Okay, now the easy one... the exhaust opening.

Simple! Open it after the power stroke as the piston is moving up on the

exhaust stroke, right? Wrong. The exhaust needs to begin opening shortly before

BDC on the power stroke. Why? Well, first off, the combustion process has

actually spent its energy about 2/3 of the way down and is moving based on the

power stroke of other cylinders at this point. If you wait and open the exhaust

as the piston starts up on the exhaust stroke, it will be pushing against the

spent gases much the

same as it does during the compression stroke. This will rob power from the

power stroke of another cylinder to work

against this force also. Opening the valve before BDC acts as a "pressure-relief"

and then all the piston has to do now is sweep the cylinder clean with its only

obstacle being the back-pressure of the exhaust system. One must be careful not

to try and take advantage of this too quickly though as it would be possible to lose the effect of

the power stroke.